軟管、接頭專業(yè)定制—里格值得信賴

網(wǎng)站地圖軟管、接頭專業(yè)定制—里格值得信賴

網(wǎng)站地圖當前位置:

產(chǎn)品中心 > 工業(yè)軟管 > RIGFLOW > 超柔PTFE橡膠軟管 >

| 常規(guī)軟管內(nèi)徑 | 實際軟管內(nèi)徑 | Bioflex Ultra 型號分類 (編織和包覆層) | 螺旋鋼絲 | 帶編織/橡膠層外徑 | 最小彎曲半徑 | 最大連續(xù)長度 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | in | mm | in | mm | Ft | Mtrs | ||

| 3/8 | 9.5 | 0.375 0.375 0.375 |

9.5 9.5 9.5 |

TO SS RC/BK/SI |

- - - |

0.47 0.50 0.68 |

12.0 12.8 17.4 |

13/8 3/4 3/4 |

35 19 19 |

100 100 100 |

30 30 30 |

| 1/2 | 15 | 0.530 0.530 0.530 0.530 |

13.5 13.5 13.5 13.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

0.654 0.700 0.800 0.845 |

16.4 17.8 20.5 21.4 |

23/8 11/2 11/2 11/2 |

60 38 38 38 |

100 100 100 100 |

30 30 30 30 |

| 5/8 | 16 | 0.650 0.650 0.650 0.650 |

16.5 16.5 16.5 16.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

0.780 0.850 0.955 0.990 |

20.1 21.6 24.3 25.2 |

21/2 13/4 13/4 13/4 |

64 45 45 45 |

100 100 100 100 |

30 30 30 30 |

| 3/4 | 20 | 0.780 0.780 0.780 0.780 |

19.8 19.8 19.8 19.8 |

TO SS PB RC/BK/SI |

√ √ √ √ |

0.920 0.980 1.085 1.120 |

23.4 24.9 27.6 28.5 |

3 2 2 2 |

75 50 50 50 |

100 100 100 100 |

30 30 30 30 |

| *7/8 | 22 | 0.875 0.875 0.875 0.875 |

22.2 22.2 22.2 22.2 |

TO SS PB RC/BK/SI |

√ √ √ √ |

1.040 1.090 1.240 1.260 |

26.4 27.7 31.5 32.0 |

31/2 21/8 21/8 21/8 |

90 55 55 55 |

100 100 100 100 |

30 30 30 30 |

| 1 | 25 | 1.030 1.030 1.030 1.030 |

26.1 26.1 26.1 26.1 |

TO SS PB RC/BK/SI |

√ √ √ √ |

1.200 1.255 1.455 1.455 |

30.5 31.9 37.0 37.0 |

43/4 23/4 23/4 23/4 |

110 70 70 70 |

100 100 100 100 |

30 30 30 30 |

| 11/4 | 32 | 1.280 1.280 1.280 1.280 |

32.5 32.5 32.5 32.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

1.490 1.555 1.740 1.755 |

37.8 39.5 44.2 44.6 |

51/2 4 4 4 |

140 100 100 100 |

100 100 100 100 |

30 30 30 30 |

| *13/8 | 35 | 1.375 1.375 1.375 1.375 |

34.9 34.9 34.9 34.9 |

TO SS PB RC/BK/SI |

√ √ √ √ |

1.590 1.665 1.850 1.865 |

40.3 42.3 47.0 47.4 |

61/2 4 4 4 |

160 100 100 100 |

100 100 100 100 |

30 30 30 30 |

| 11/2 | 40 | 1.530 1.530 1.530 1.530 |

38.8 38.8 38.8 38.8 |

TO SS PB RC/BK/SI |

√ √ √ √ |

1.750 1.840 2.020 2.035 |

44.5 46.7 51.4 51.7 |

7 51/2 51/2 51/2 |

180 140 140 140 |

100 100 100 100 |

30 30 30 30 |

| *17/8 | 48 | 1.875 1.875 1.875 1.875 |

47.6 47.6 47.6 47.6 |

TO SS PB RC/BK/SI |

√ √ √ √ |

2.145 2.220 2.410 2.410 |

54.4 56.4 61.3 61.3 |

11 65/8 65/8 65/8 |

280 170 170 170 |

100 100 100 100 |

30 30 30 30 |

| 2 | 50 | 2.030 2.030 2.030 2.030 |

51.5 51.5 51.5 51.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

2.320 2.390 2.575 2.580 |

58.9 60.7 65.4 65.6 |

12 8 8 8 |

300 200 200 200 |

100 100 100 100 |

30 30 30 30 |

| 21/2 | 65 | 2.508 2.508 2.508 2.508 |

63.7 63.7 63.7 63.7 |

TO SS PB RC/BK/SI |

√ √ √ √ |

2.882 2.965 3.181 3.169 |

73.2 75.3 80.8 80.5 |

173/4 117/8 117/8 117/8 |

450 300 300 300 |

60 60 60 60 |

18 18 18 18 |

| 3 | 80 | 3.024 3.024 3.024 3.024 |

76.8 76.8 76.8 76.8 |

TO SS PB RC/BK/SI |

√ √ √ √ |

3.394 3.457 3.732 3.654 |

86.2 87.8 94.8 92.8 |

203/4 133/4 133/4 133/4 |

525 350 350 350 |

50 50 50 50 |

15 15 15 15 |

*7/8”, 13/8” 和 17/8” 三個尺寸的軟管只能扣壓翻邊的TC接頭和翻邊的I-Lined接頭

尺寸、型號分類、耐受壓力和單位長度重量

| 常用軟管內(nèi)徑 | 實際軟管內(nèi)徑 | 實際軟管內(nèi)徑 | 螺旋鋼絲 | **最大耐受工作壓力 | 爆破壓力 | 單位長度重量 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | Bar | psi | Bar | psi | Kg/mtr | lb/ft | ||

| 3/8 | 9.5 | 0.375 0.375 0.375 |

9.5 9.5 9.5 |

TO SS RC/BK/SI |

- - - |

5 80 80 |

72 1160 1160 |

20 500 500 |

290 7200 7200 |

.06 .14 .22 |

.04 .09 .15 |

| 1/2 | 15 | 0.530 0.530 0.530 0.530 |

13.5 13.5 13.5 13.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

5 70 35 70 |

72 1015 500 1015 |

20 400 140 400 |

290 5800 2000 5800 |

.15 .29 .22 .39 |

.10 .19 .15 .26 |

| 5/8 | 16 | 0.650 0.650 0.650 0.650 |

16.5 16.5 16.5 16.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

5 65 33 65 |

72 940 480 940 |

20 380 130 380 |

290 5500 1900 5500 |

.17 .35 .25 .47 |

.11 .23 .17 .31 |

| 3/4 | 20 | 0.780 0.780 0.780 0.780 |

19.8 19.8 19.8 19.8 |

TO SS PB RC/BK/SI |

√ √ √ √ |

5 60 30 60 |

72 870 440 870 |

20 300 120 300 |

290 4350 1750 4350 |

.20 .40 .28 .55 |

.13 .27 .19 .37 |

| *7/8 | 22 | 0.875 0.875 0.875 0.875 |

22.2 22.2 22.2 22.2 |

TO SS PB RC/BK/SI |

√ √ √ √ |

4 55 27.5 55 |

60 800 400 800 |

16 220 110 220 |

230 3200 1600 3200 |

.34 .60 .44 .82 |

.23 .40 .30 .55 |

| 1 | 25 | 1.030 1.030 1.030 1.030 |

26.1 26.1 26.1 26.1 |

TO SS PB RC/BK/SI |

√ √ √ √ |

4 50 25 50 |

60 720 360 720 |

16 200 100 200 |

230 2900 1450 2900 |

.36 .63 .47 .92 |

.24 .42 .31 .62 |

| 11/4 | 32 | 1.280 1.280 1.280 1.280 |

32.5 32.5 32.5 32.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

3 45 23 45 |

43 650 330 650 |

12 180 90 180 |

175 2600 1300 2600 |

.45 .85 .72 1.15 |

.30 .57 .48 .77 |

| *13/8 | 35 | 1.375 1.375 1.375 1.375 |

34.9 34.9 34.9 34.9 |

TO SS PB RC/BK/SI |

√ √ √ √ |

2 40 20 40 |

29 580 290 580 |

8 160 80 160 |

115 2320 1160 2320 |

.68 1.14 1.00 1.51 |

.46 .77 .67 1.01 |

| 11/2 | 40 | 1.530 1.530 1.530 1.530 |

38.8 38.8 38.8 38.8 |

TO SS PB RC/BK/SI |

√ √ √ √ |

2 40 20 40 |

29 580 290 580 |

8 160 80 160 |

116 2320 1160 2320 |

.66 1.10 .90 1.55 |

.44 .74 .60 1.04 |

| *17/8 | 48 | 1.875 1.875 1.875 1.875 |

47.6 47.6 47.6 47.6 |

TO SS PB RC/BK/SI |

√ √ √ √ |

2 35 18 35 |

29 500 250 500 |

8 140 72 140 |

115 2000 1040 2000 |

1.12 1.70 1.40 2.22 |

.75 1.14 .94 1.49 |

| 2 | 50 | 2.030 2.030 2.030 2.030 |

51.5 51.5 51.5 51.5 |

TO SS PB RC/BK/SI |

√ √ √ √ |

2 30 15 30 |

29 430 215 430 |

8 120 60 120 |

116 1750 870 1750 |

1.25 1.90 1.60 2.56 |

.84 1.27 1.07 1.71 |

| 21/2 | 65 | 2.508 2.508 2.508 2.508 |

63.7 63.7 63.7 63.7 |

TO SS PB RC/BK/SI |

√ √ √ √ |

4 20 12 20 |

60 290 174 290 |

16 80 48 80 |

230 1160 696 1160 |

1.99 2.58 2.38 3.59 |

1.33 1.73 1.59 2.41 |

| 3 | 80 | 3.024 3.024 3.024 3.024 |

76.8 76.8 76.8 76.8 |

TO SS PB RC/BK/SI |

√ √ √ √ |

3 15 10 15 |

43 215 145 215 |

12 60 40 60 |

175 870 580 870 |

2.45 3.13 3.02 4.30 |

1.64 2.10 2.02 2.96 |

* 7/8”, 13/8” 和 17/8” 三個尺寸的軟管只能扣壓翻邊的TC接頭和翻邊的I-Lined接頭

** 軟管總成的最大工作壓力會受限于兩端接頭的最大工作壓力和自身軟管的最大工作壓力。

廣州市南沙區(qū) ( 廣東自由貿(mào)易試驗區(qū) ) 珠電路69號

復合軟管的優(yōu)勢與輸油軟管的性能

塑料復合軟管優(yōu)點與發(fā)展歷史

復合軟管的快速發(fā)展與定義

國內(nèi)軟管制作與復合軟管特點

管道完整性管理

國內(nèi)軟管制作與復合軟管特點

復合軟管材料與防靜電軟管知識

防靜電軟管適用與20世紀的復合軟管

化工軟管作用與輸油復合軟管的物流

復合軟管近年來

我國油氣管道發(fā)展展望

國外管道風險評價技術(shù)的發(fā)展

輸油軟管腐蝕的影響因素分析

分析塑料復合軟管市場

輸油軟管的適用領(lǐng)域及維護事項

復合軟管的耐蝕性及耐高溫性

復合軟管的特殊工藝方法及靜電逸散性能

復合軟管的操作使用要領(lǐng)

化工軟管的關(guān)鍵性作用及使用安全可靠

化工軟管的應用領(lǐng)域正在日趨擴大

化工軟管適用、用途、分類、性能優(yōu)勢

復合軟管安全性能與應用領(lǐng)域分類

輸油軟管特性與復合軟管特點

復合軟管檢查與化工軟管特色

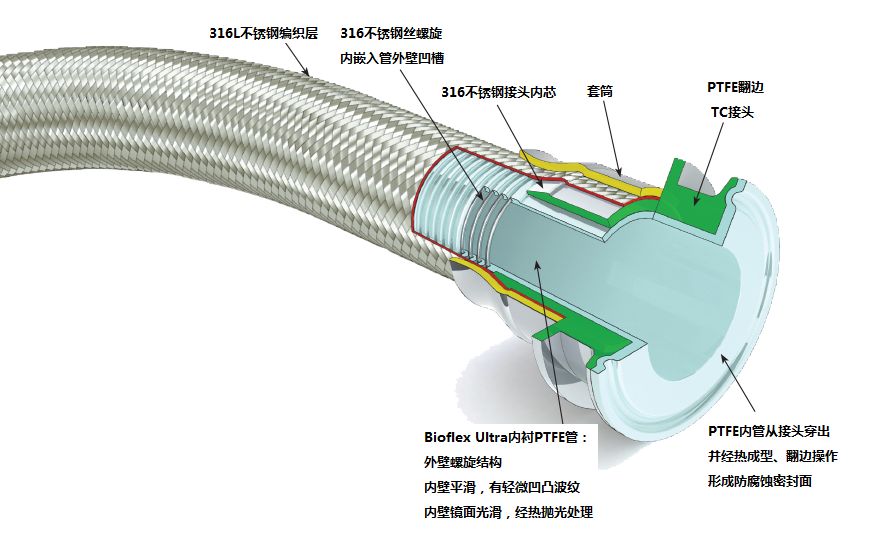

超柔PTFE橡膠軟管,